Additive manufacturing

Our ALTERINOV by CTTC platform comprises a dozen printers, applying single or hybrid process for 3D printing or direct ink writing.

From powder to object

ALTERINOV by CTTC platform

Additive processes can be categorised into two families: 3D printing and direct writing. 3D printing refers to methods where the part to be manufactured is produced directly in a tank filled with material, whereas direct ink writing is based on the deposition of extruded or sprayed material through one or multiple nozzles onto a bare substrate.

Laser stereolithography

The principle of stereolithography (SLA) is to build the object from a series of layers of 2D patterns, using a light source to polymerise a paste composed of photosensitive resin and a ceramic powder. The resulting composite then undergoes heat treatments to remove organics and densify the part by sintering of the ceramic material.

To date, this is the only technology that enables high dimensional tolerances to be achieved, while at the same time providing mechanical properties comparable to those obtained using conventional shaping processes.

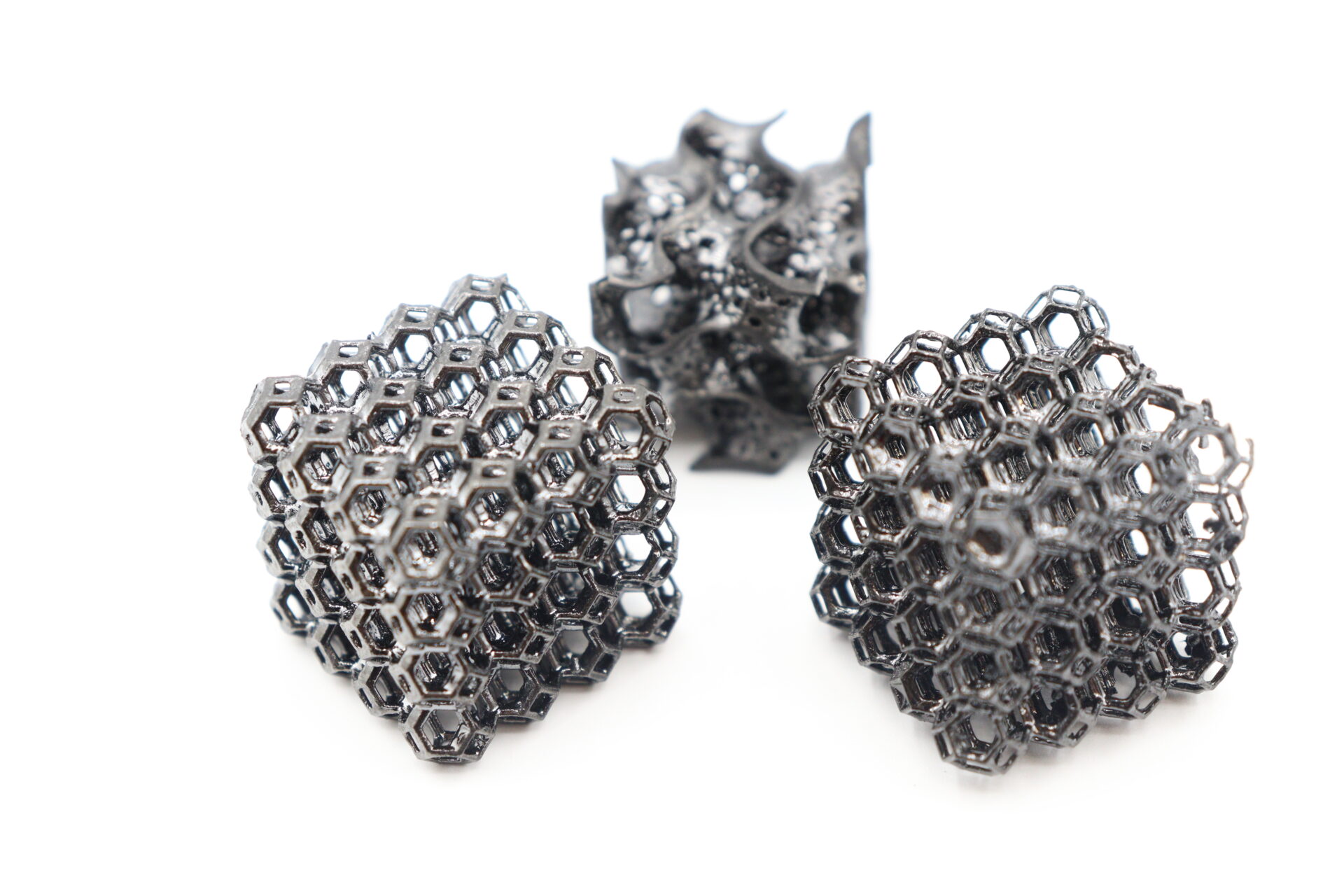

Binder spraying on powder bed

The principle of this process, also known as Binder Jetting, is based on the solidification of a serie of layers of 2D patterns by bonding grains of powder together using a binder dispensed by an inkjet print head. Once the part has been completely manufactured, it is simply cleaned by removing the 'unbonded' powder using a brush or an air jet. This process does not require the building of supports, as this function is performed by the powder bed itself.

This technology is particularly interesting for its speed of manufacture and the production of large parts. These advantages have to be weighed against the need to use powders with a high particle size and the residual porosity in the materials.

Micro-extrusion

Micro-extrusion (also known as Robocasting process) involves a number of manufacturing approaches, depending on the type of material to be printed or the shape required. The principle is based on the extrusion of a material through a nozzle, which is placed in contact with the substrate on which the part has to be built, and then in contact with each lower layer as the manufacturing process progresses, to ensure that the material adheres between each layer.

The materials can be in the form of wires (FDM technique or molten wire), pastes (cords extrusion technique), or inks (dispensing technique).

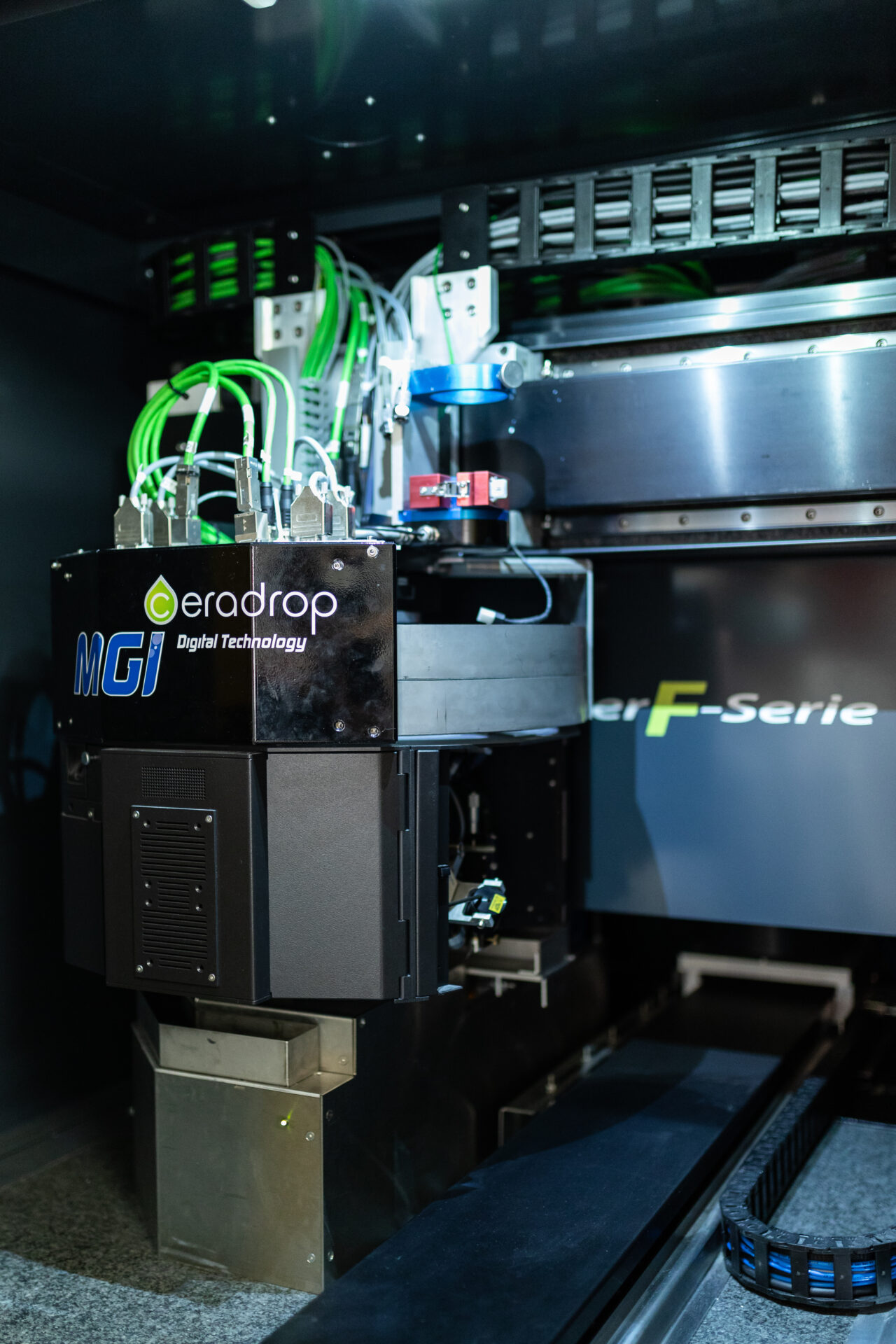

Ink jet printing

Ink jet printing is a non-contact matrix printing technique in which fine drops of ink are jetted onto a flat substrate. There are two categories: continuous jet approach and drop-on-demand approach.

Inkjet technology generates three-dimensional structures layer by layer, by successive deposits of micro-droplets of ceramic, metallic or polymer inks. Each layer needs to be dried before a new layer can be stacked. Layer after layer, a 2.5D component is obtained.

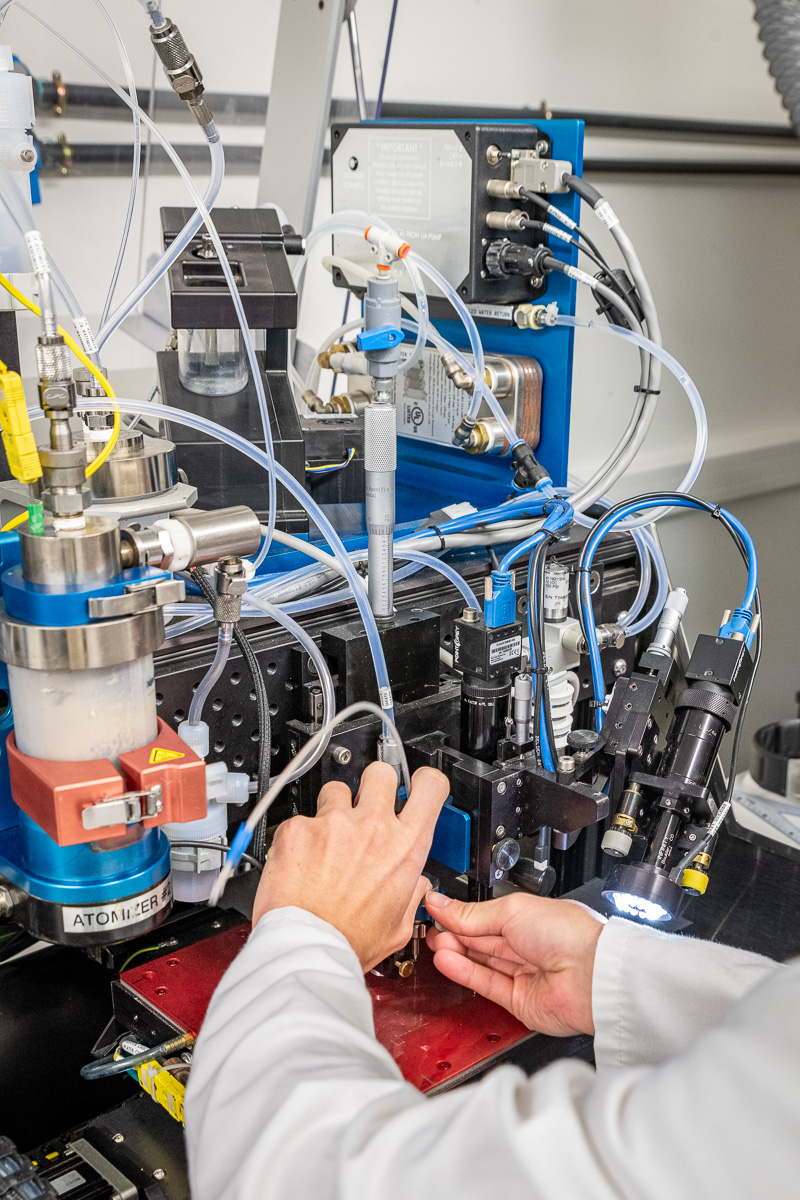

Aerosol Jet Printing

Aerosol Jet Printing uses a single nozzle to generate a stream of focused micro-droplets (liquid aerosol), which is controlled to deposit ink in a pre-defined pattern on a substrate. Discrete patterns can be obtained by placing a controlled shutter under the nozzle.

This technology is extremely flexible. It is equally well suited to flat, curved or textured surfaces; filling cavities or vias; and creating 3D patterns.