Prototyping

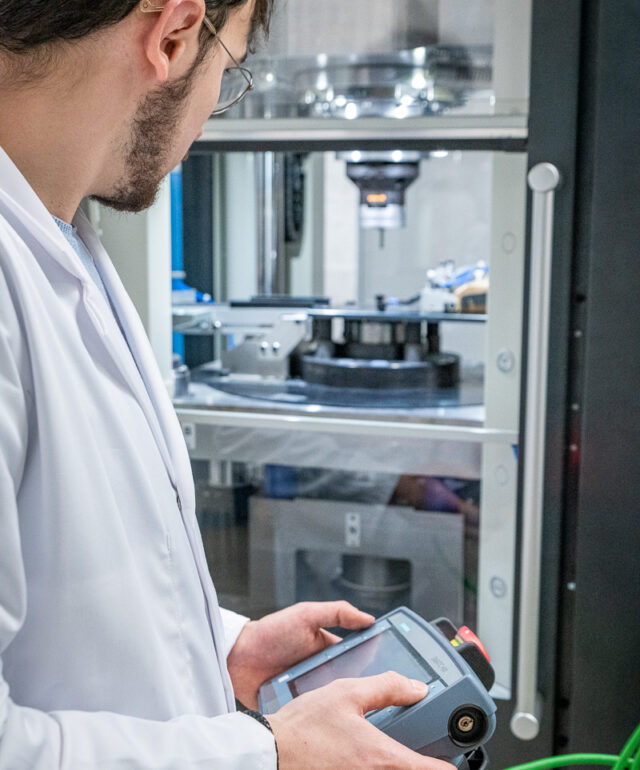

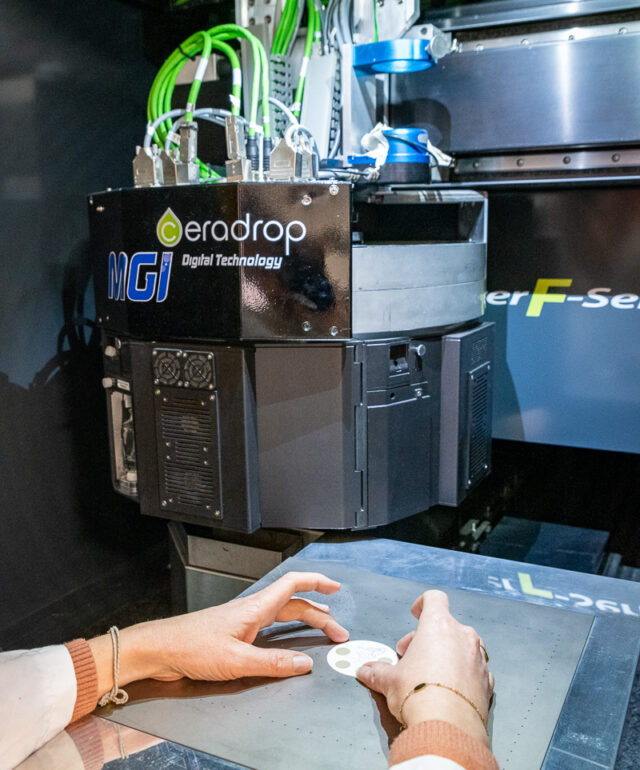

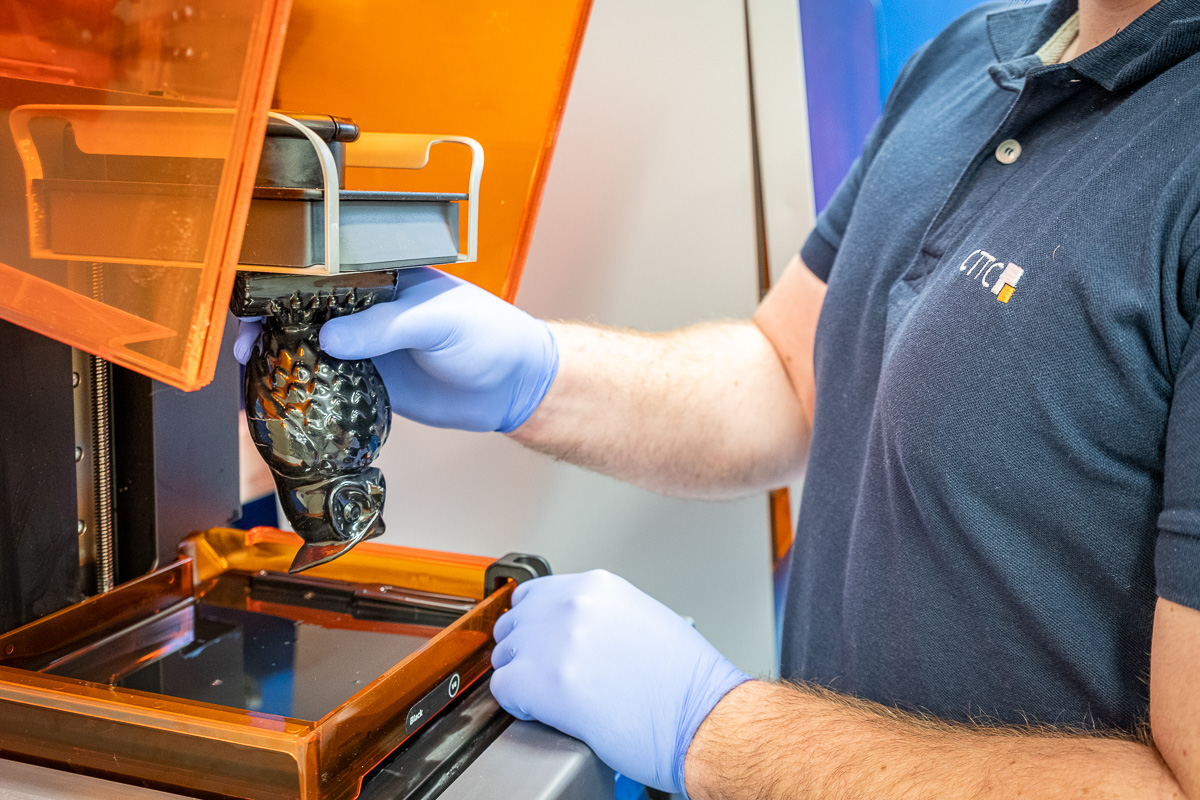

Thanks to its equipment and skills, the CTTC is able to produce your prototypes on request. Equipped with a range of design tools, forming, heat treatment and ceramic finishing equipment, we can produce prototypes to meet your requirements.

Our Design Office can help you define your specifications, design your products and produce your parts digitally using CAD/CAM tools (3D modelling, 3D scanning, topology, etc.). We can also use your 2D drawings or 3D models if required. Our team then selects the best shaping process (conventional, additive manufacturing) based on the technical constraints of your part (material, geometry, dimensional dimensions, tolerances, etc.) and its environment (assembly, mechanical and thermal constraints). Our expertise enables us to select the appropriate heat treatment cycles to suit the final density targeted, and to add a finishing step if necessary (machining, grinding, polishing, etc.).